System Maintenance: 7 Powerful Strategies for Peak Performance

Welcome to the ultimate guide on system maintenance—your go-to resource for keeping systems running smoothly, efficiently, and securely. Whether you’re managing IT infrastructure, industrial machinery, or software platforms, effective system maintenance is the backbone of reliability and productivity. Let’s dive into the essentials that will transform how you maintain your systems.

What Is System Maintenance and Why It Matters

System maintenance refers to the routine activities performed to ensure that hardware, software, networks, and other technological or mechanical systems operate efficiently and remain free from failures. It’s not just about fixing problems—it’s about preventing them before they occur.

Defining System Maintenance in Modern Contexts

In today’s digital-first world, system maintenance spans across multiple domains: IT systems, cloud environments, manufacturing equipment, and even embedded systems in smart devices. The core idea remains the same—preserving functionality, optimizing performance, and extending lifespan.

- Prevents unexpected downtime

- Improves system security

- Enhances user experience and productivity

According to ISO 14224, a standardized approach to maintenance data collection significantly improves operational efficiency in industrial settings.

The Cost of Neglecting System Maintenance

Ignoring system maintenance can lead to catastrophic consequences. A 2023 report by Gartner revealed that unplanned downtime costs enterprises an average of $5,600 per minute. For large-scale operations, this can quickly escalate into millions of dollars in lost revenue, not to mention reputational damage.

“An ounce of prevention is worth a pound of cure.” – Benjamin Franklin

This timeless quote perfectly encapsulates the philosophy behind proactive system maintenance. Reactive fixes are often more expensive, time-consuming, and disruptive than scheduled upkeep.

The 4 Core Types of System Maintenance

Understanding the different types of system maintenance is crucial for developing a comprehensive strategy. Each type serves a unique purpose and is applied based on system requirements, risk levels, and operational goals.

Corrective (Reactive) Maintenance

Corrective maintenance is performed after a system failure has occurred. While it may seem inefficient, it’s still relevant in low-risk or non-critical systems where downtime doesn’t significantly impact operations.

- Triggered by system failure

- Often involves emergency repairs

- Higher long-term costs due to collateral damage

For example, replacing a failed hard drive in a non-redundant server is a form of corrective maintenance. However, relying solely on this approach increases the risk of data loss and service disruption.

Preventive (Planned) Maintenance

Preventive maintenance is scheduled at regular intervals to reduce the likelihood of failures. This is one of the most widely adopted forms of system maintenance in both IT and industrial sectors.

- Includes software updates, hardware inspections, and cleaning

- Reduces unexpected breakdowns by up to 70% (source: MaintenanceWorld)

- Can be time-based or usage-based

Examples include monthly antivirus scans, quarterly server reboots, or annual calibration of industrial sensors.

Predictive Maintenance

Predictive maintenance uses real-time data and analytics to anticipate failures before they happen. It leverages technologies like IoT sensors, machine learning, and condition monitoring.

- Monitors system health continuously

- Uses AI to analyze trends and predict failures

- High ROI in complex or high-value systems

For instance, a manufacturing plant might use vibration sensors on motors to detect early signs of bearing wear. By addressing issues only when needed, companies save on labor and parts while maximizing uptime.

Perfective (Improvement-Oriented) Maintenance

Perfective maintenance focuses on enhancing system performance, usability, or functionality. Unlike corrective or preventive tasks, this type isn’t driven by failure but by the need for optimization.

- Involves software upgrades, UI improvements, or performance tuning

- Supports scalability and future-proofing

- Often part of digital transformation initiatives

An example is refactoring legacy code to improve application speed or migrating to a more efficient database system.

System Maintenance in IT Infrastructure

IT infrastructure is the backbone of modern organizations, encompassing servers, networks, databases, and end-user devices. Effective system maintenance in this domain ensures data integrity, cybersecurity, and seamless operations.

Server and Network Maintenance

Servers and network devices require consistent monitoring and upkeep to handle traffic loads and prevent outages. Routine tasks include firmware updates, log analysis, and bandwidth optimization.

- Regular patching of operating systems and network firmware

- Monitoring for unusual traffic patterns (potential security threats)

- Performing failover tests to ensure redundancy

The National Vulnerability Database (NVD) by NIST provides critical information on known vulnerabilities, helping IT teams prioritize patches.

Database Maintenance Best Practices

Databases store mission-critical information, making their maintenance vital. Poorly maintained databases can suffer from slow queries, data corruption, or even complete failure.

- Regular index rebuilding and statistics updates

- Automated backup and recovery testing

- Query optimization and dead lock monitoring

Tools like SQL Server Maintenance Plans help automate routine tasks, reducing human error and ensuring consistency.

Cloud System Maintenance

With the rise of cloud computing, system maintenance has evolved. While cloud providers handle hardware upkeep, organizations are still responsible for configuration, security, and performance tuning.

- Managing IAM (Identity and Access Management) policies

- Monitoring resource utilization and auto-scaling settings

- Ensuring compliance with data protection regulations (e.g., GDPR, HIPAA)

AWS, Azure, and Google Cloud offer built-in monitoring tools like CloudWatch, Azure Monitor, and Stackdriver, enabling proactive system maintenance in virtualized environments.

Industrial and Mechanical System Maintenance

Beyond IT, system maintenance plays a critical role in manufacturing, energy, transportation, and other industrial sectors. Here, the stakes are often higher, with safety and regulatory compliance at the forefront.

Maintenance of Production Equipment

In manufacturing, equipment downtime can halt entire production lines. System maintenance ensures machines operate at peak efficiency.

- Lubrication, alignment, and calibration of machinery

- Replacing worn-out belts, bearings, or seals

- Using CMMS (Computerized Maintenance Management Systems) for tracking

Companies like Siemens and GE offer predictive maintenance solutions integrated with their industrial IoT platforms.

Safety and Regulatory Compliance

Industrial system maintenance must adhere to strict safety standards. Regulatory bodies such as OSHA (Occupational Safety and Health Administration) mandate regular inspections and documentation.

- Annual pressure vessel inspections

- Fire suppression system testing

- Electrical safety audits

Failure to comply can result in fines, shutdowns, or legal liability. A well-documented system maintenance log is essential for audit readiness.

Role of Automation in Industrial Maintenance

Automation is revolutionizing industrial system maintenance. Robots, drones, and AI-driven analytics are being used to inspect hard-to-reach areas and predict equipment failures.

- Drones inspecting wind turbines or pipelines

- AI analyzing thermal imaging to detect overheating components

- Automated lubrication systems reducing manual labor

According to a McKinsey report, predictive maintenance can reduce maintenance costs by 10–40% and downtime by 50%.

Software System Maintenance: Beyond Bug Fixes

Software doesn’t wear out like hardware, but it still requires ongoing system maintenance to remain functional, secure, and user-friendly. This includes everything from mobile apps to enterprise software suites.

Correcting Bugs and Security Vulnerabilities

Even well-tested software contains bugs. Regular updates are essential to fix these issues and protect against exploits.

- Applying security patches within 48 hours of release (critical)

- Conducting penetration testing and code reviews

- Using automated tools like Snyk or Dependabot to detect vulnerabilities

The 2021 Log4j vulnerability (Log4Shell) highlighted the importance of timely software maintenance—even open-source libraries need constant oversight.

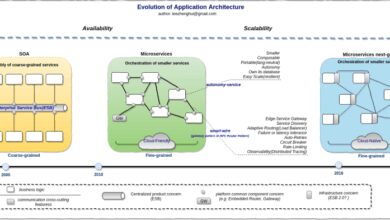

Performance Optimization and Scalability

As user demand grows, software must scale efficiently. System maintenance includes optimizing code, database queries, and server configurations.

- Caching strategies to reduce load times

- Load testing under peak conditions

- Migrating to microservices architecture for better scalability

Netflix, for example, uses chaos engineering (via tools like Chaos Monkey) to proactively test system resilience and performance under stress.

User Experience and Feature Updates

Modern software evolves based on user feedback and market trends. Perfective system maintenance ensures the software stays relevant and competitive.

- Redesigning outdated UI elements

- Adding new integrations (e.g., API connections)

- Improving accessibility and mobile responsiveness

Regular release cycles (e.g., Agile sprints) help incorporate these updates without disrupting core functionality.

Best Practices for Effective System Maintenance

Successful system maintenance isn’t just about doing tasks—it’s about doing them right. Implementing best practices ensures consistency, accountability, and long-term success.

Create a Comprehensive Maintenance Plan

A structured plan outlines what needs to be maintained, how often, and by whom. It should include checklists, schedules, and escalation procedures.

- Define maintenance windows to minimize disruption

- Assign roles and responsibilities clearly

- Integrate with change management processes

The plan should be living document, updated regularly based on performance data and feedback.

Leverage Maintenance Management Software

Manual tracking is error-prone and inefficient. Modern CMMS and EAM (Enterprise Asset Management) platforms streamline system maintenance workflows.

- Automate work order generation

- Track asset history and maintenance costs

- Generate compliance reports and KPI dashboards

Popular tools include UpKeep, Fiix, and IBM Maximo—each offering cloud-based solutions for real-time visibility.

Train and Empower Maintenance Teams

Even the best tools are ineffective without skilled personnel. Ongoing training ensures teams stay updated on new technologies and procedures.

- Conduct regular workshops on safety and new tools

- Encourage certification programs (e.g., CompTIA, CMRP)

- Foster a culture of accountability and continuous improvement

Empowered teams are more likely to identify issues early and suggest process improvements.

The Future of System Maintenance: AI and Automation

The landscape of system maintenance is rapidly evolving. Emerging technologies are making maintenance smarter, faster, and more predictive than ever before.

Artificial Intelligence in Predictive Maintenance

AI algorithms can analyze vast amounts of sensor data to detect anomalies and predict failures with high accuracy.

- Machine learning models trained on historical failure data

- Natural language processing for analyzing maintenance logs

- AI-powered chatbots assisting technicians with troubleshooting

Google’s DeepMind has already demonstrated AI’s potential in optimizing data center cooling, reducing energy use by 40%—a form of system maintenance that boosts efficiency.

Autonomous Maintenance and Robotics

In the future, robots may perform routine maintenance tasks without human intervention. This is already happening in some advanced facilities.

- Self-diagnosing systems that order replacement parts automatically

- Maintenance drones inspecting bridges or power lines

- Robotic arms servicing machinery in hazardous environments

While full autonomy is still years away, semi-autonomous systems are already enhancing safety and efficiency.

Integration with Smart Cities and IoT Ecosystems

As cities become smarter, system maintenance will extend to public infrastructure—traffic lights, water systems, and energy grids—all interconnected via IoT.

- Real-time monitoring of urban infrastructure

- Automated alerts for potholes, leaks, or outages

- Data-driven decision-making for city planners

Cities like Singapore and Barcelona are leading the way in using IoT for predictive urban maintenance, reducing costs and improving citizen satisfaction.

Common Challenges in System Maintenance and How to Overcome Them

Despite its importance, system maintenance often faces obstacles that hinder effectiveness. Recognizing these challenges is the first step toward overcoming them.

Budget Constraints and Resource Limitations

Many organizations underfund maintenance, prioritizing short-term savings over long-term reliability.

- Solution: Demonstrate ROI through cost-benefit analysis

- Use predictive maintenance to reduce unnecessary spending

- Outsource non-core maintenance tasks when needed

A study by Deloitte found that every $1 invested in preventive maintenance saves $4 in corrective costs.

Lack of Skilled Personnel

The growing complexity of systems demands highly skilled technicians, but there’s a global shortage in technical talent.

- Solution: Invest in training and apprenticeship programs

- Adopt user-friendly tools that reduce skill barriers

- Leverage remote expert support via AR/VR

Augmented reality (AR) glasses, like Microsoft HoloLens, allow remote experts to guide on-site technicians in real time.

Poor Documentation and Knowledge Transfer

When experienced staff leave, critical maintenance knowledge often walks out the door.

- Solution: Implement a centralized knowledge base

- Record procedures and create video tutorials

- Use CMMS to log all maintenance activities

Documenting every repair, update, and inspection ensures continuity and reduces onboarding time for new staff.

What is the difference between preventive and predictive maintenance?

Preventive maintenance is scheduled at fixed intervals (e.g., every 3 months), regardless of the system’s actual condition. Predictive maintenance, on the other hand, uses real-time data and analytics to perform maintenance only when needed, based on the system’s health. Predictive is more efficient and cost-effective but requires advanced monitoring tools.

How often should system maintenance be performed?

The frequency depends on the system type and criticality. IT systems may require weekly updates, while industrial equipment might need monthly inspections. Critical systems often follow manufacturer guidelines or regulatory requirements. Using condition-based monitoring allows for dynamic scheduling based on actual usage and wear.

Can system maintenance prevent cyberattacks?

Yes, absolutely. Regular system maintenance includes applying security patches, updating antivirus definitions, and hardening configurations—all of which reduce vulnerabilities. Unpatched systems are a primary target for cybercriminals, as seen in major breaches like WannaCry, which exploited outdated Windows systems.

What tools are essential for effective system maintenance?

Essential tools include monitoring software (e.g., Nagios, Zabbix), CMMS platforms (e.g., Fiix, UpKeep), vulnerability scanners (e.g., Nessus), and backup solutions (e.g., Veeam). For IT, tools like PowerShell or Ansible help automate routine tasks, improving consistency and reducing human error.

Is system maintenance necessary for cloud-based applications?

Yes. While cloud providers manage the underlying hardware, organizations are responsible for maintaining their applications, configurations, access controls, and data. Regular updates, security audits, and performance tuning are crucial even in cloud environments to ensure reliability and compliance.

System maintenance is not a one-time task but an ongoing commitment to reliability, security, and efficiency. From IT infrastructure to industrial machinery and software platforms, proactive maintenance prevents costly failures, enhances performance, and supports long-term success. By embracing best practices, leveraging modern tools, and preparing for future innovations like AI and automation, organizations can stay ahead of the curve. The key is to shift from reactive fixes to a strategic, data-driven approach that views maintenance not as a cost, but as a critical investment in operational excellence.

Recommended for you 👇

Further Reading: